傳統的納米注塑,需要進行表面處理,同時對金屬,塑料性能,模具結構,注塑參數有很高的要求。日本寶理開發了一種Quick-10 技術,無需表面處理即可讓塑料和金屬有效的連接一起,這種技術利用對金屬嵌件快速的升溫和降溫,僅在注塑過程中就能夠完成塑膠和金屬的粘接。寶理已經開發可以用于Quick-10 技術的PBT,和PPS。

Engineering thermoplastics supplier Polyplastics has developed a technology that improves metal-plastic bonding of composite parts for the automotive and electrical/electronics industries without the need for pre-treatment of the metal inserts.

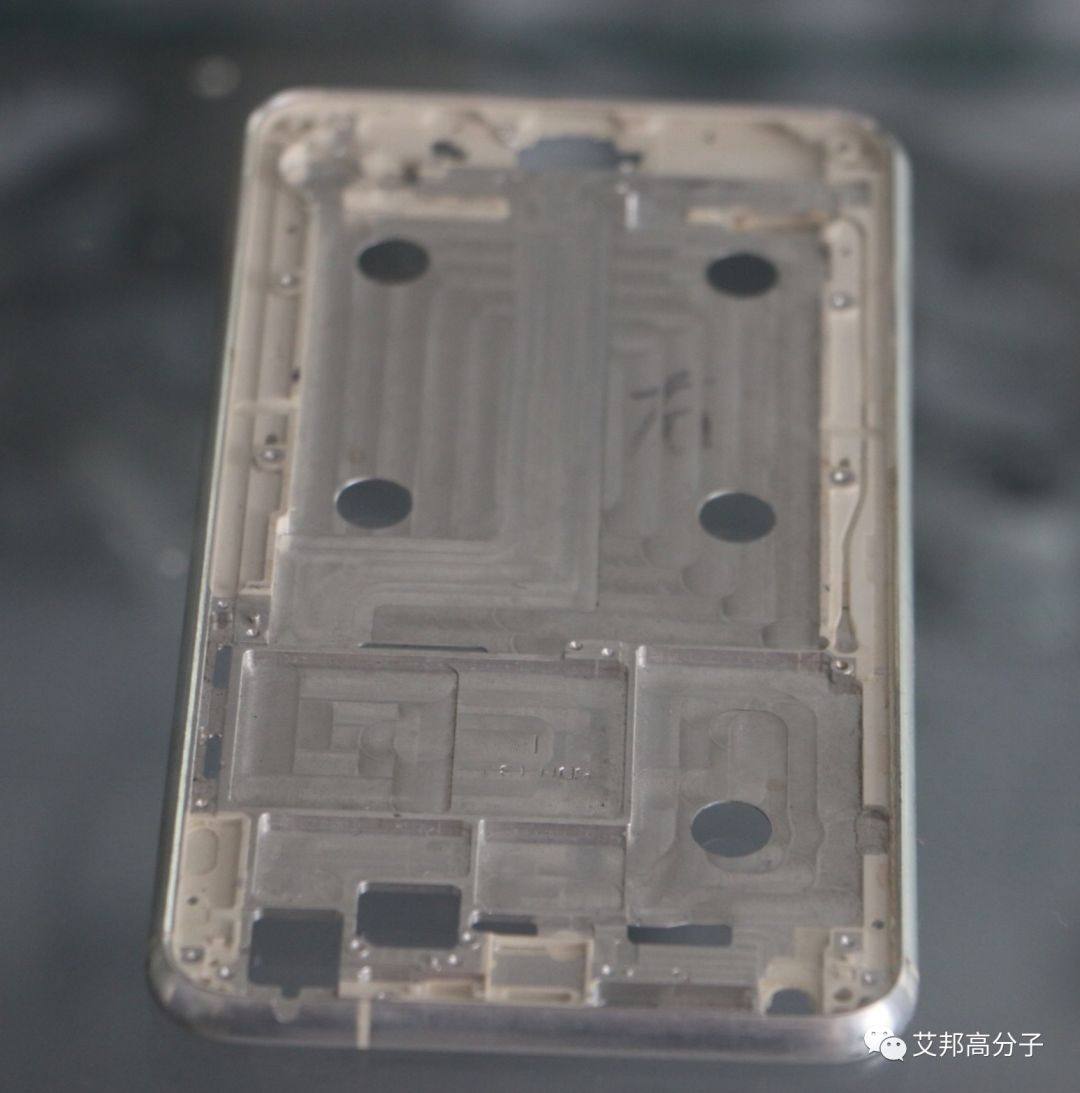

Polyplastics’ Quick-10 metal-plastic bonding technology has been used in mobile device parts (mobile phones, tablets, digital cameras) and some auto-related parts.

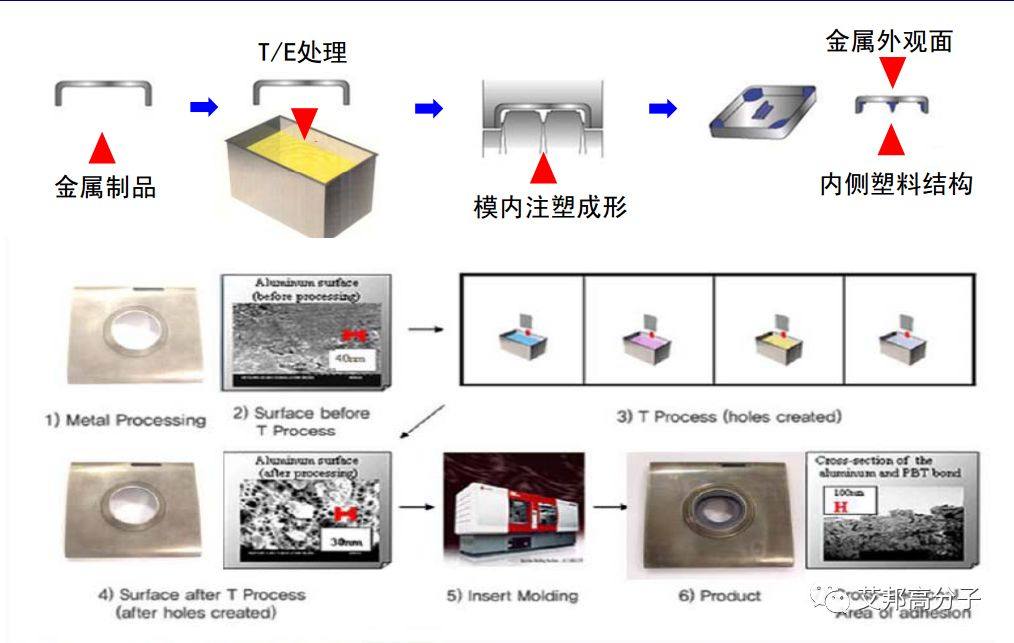

Direct metal-plastic bonding is a process which typically employs metal insert molding. In the traditional process, metal inserts and plastics are firmly bonded via introduction of molten plastic through injection molding to metal inserts which have already undergone appropriate surface treatment. These metal-plastic composites combine the properties of metals (high rigidity, electrical conductivity) and engineering plastics (low density, electrical insulation). However, while numerous factors (metal inserts, plastics, mold structure, injection molding parameters, etc.) generally have adverse effects and prevent stable bonding, Polyplastics has made progress with successful bonding through its Quick-10 technology.

The Quick-10 process usesrapid heating and cooling of metal inserts to realize direct metal-plastic bonding through the injection molding process alone, without any special surface treatment for the metal.The plastics employed must, however exhibit properties such as interface affinity, surface transferability (flowability), and low shrinkage to realize good bonding. To this end, Polyplastics has developed appropriate polyphenylene sulfide (PPS) and polybutylene terephthalate (PBT) grades for the process

The Quick-10 process uses rapid heating and cooling of metal inserts to realize direct metal-plastic bonding through the injection molding process alone, without any special surface treatment for the metal. The plastics employed must, however exhibit properties such as interface affinity, surface transferability (flowability), and low shrinkage to realize good bonding. To this end, Polyplastics has developed appropriate polyphenylene sulfide (PPS) and polybutylene terephthalate (PBT) grades for the process

補充資料:

日本大成塑料(Taiseiplas)株式會社于2002年發明了納米成型技術(NMT)。大成第一個字母為T,所以命名T處理。我國研究人員改變了納米孔形成方式,衍生了不同的處理方法,其中,在通電的情況下進行的處理方法被稱為E處理,字母E是電的縮寫

圖:納米注塑工藝最重要的應用:手機金屬結構件與塑膠結合

本文英文來源:

Metal-plastic bonding technology developed for automotive and electrical/electronics

by:

Stephen Moore

Automotive and Mobility

Materials & Assembly,Consumer Electronics,Injection Molding,Materials

May 21, 2018

| 歡迎長按二維碼,加入艾邦塑膠手機外殼群,備注 “IMT”,和專業的人士進行交流。 |

活動推薦:作為仿玻璃的重點工藝,2.5D /3D復合板材,IMT將在今年下半年和明年快速放量,6月30日我們舉行塑膠外殼論壇:

第二屆手機塑膠外殼(IMT、復合板材)技術與應用論壇

5G時代,塑膠重生

2018 年6 月30 日深圳觀瀾格蘭云天酒店

主要議題:

序 | 演講議題 | 演講人 |

1 | IMT在手機中的應用 | 征集中 |

2 | IMT薄膜設計 | 征集中 |

3 | 手機裝飾紋理趨勢 | 征集中 |

4 | IMT自動化工藝實現 | 東莞市力超精密機械有限公司 |

5 | 手機中框IMT專用材料介紹 | 中塑新材料 |

6 | 高壓空氣成型復合蓋板最新動態 | 東莞市新橋聯復合材料科技有限公司 |

7 | 3d噴涂防指紋加硬工藝全方案 | 深圳市智宇材料科技有限公司 |

8 | PVD鍍膜的效率以及良率提升方案 | 姚強 |

9 | 高壓復合板材的最新進展 | 東莞市震宇模具塑膠實業有限公司 |

10 | 塑膠外殼相關新工藝,新設備 | 擬邀請群達塑膠電子(深圳)有限公司 |

11 | 2.5D與3D復合板材的材料選擇與應用 | 四川龍華光電薄膜股份有限公司 |

12 | uv轉印材料與紋理設計 | 惠州市德佑威電子材料有限公司 |

報名鏈接:

方式1:在線登記報名;

方式2:請加微信并發名片報名;

鄧小姐:15817337805,微信同電話號碼

江先生:18666186648,微信同電話號碼。

閱讀原文,即可報名

始發于微信公眾號: 艾邦高分子