溫馨提示:如果您是高分子行業相關產業鏈,如塑料,彈性體,橡膠,模具,鞋材,3D打印耗材,塑料包裝,PP、PE期貨、鈣粉,白油,抗氧劑等助劑行業從業者,請點擊標題下面的“艾邦高分子”進行關注

根據Robert Eller Associates LLC總裁兼資深顧問Robert Eller,在汽車行業的強勁推動下,北美熱塑性彈性體(TPE)需求在2014年有望上漲6-7%。

BATH, OHIO — NorthAmerican thermoplastic elastomer demand is set to grow by 6-7 percent in 2014,helped in part by strong growth from the automotive sector, according tolongtime consultant Robert Eller.(關注微信:polytpe,然后回復:“TPE”即可查看更多關于TPE市場信息)

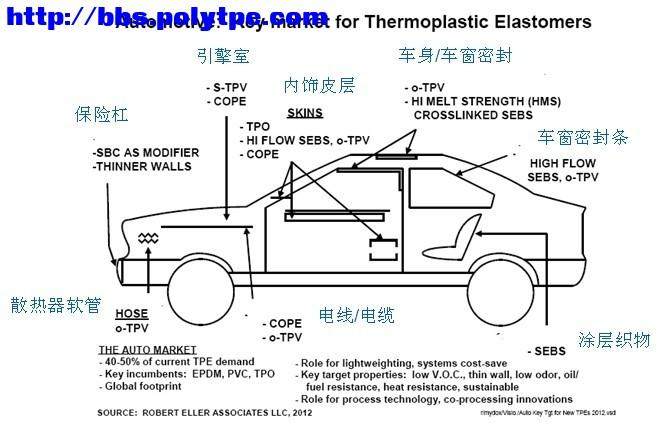

這樣的增長率高于2013年,因為“總體而言,今年的經濟形勢好于去年,”Eller在近期的一次采訪中說道。汽車市場的蓬勃發展無疑是推動TPE需求的重要因素,無論在北美還是全球,這一市場對TPE的需求至少占總需求的1/2。

That rate ishigher than that seen in 2013, because “in general, the economy is doingbetter,” Eller said in a recent interview in Bath. This comeback has beenfueled by higher build numbers in the auto market, which accounts for at leasthalf of TPE demand, both in North America and worldwide.(關注微信:polytpe,然后回復:“汽車”即可查看更多關于車用TPE市場信息)

就全球而言,中國和印度對車用TPE的需求增長潛力最為可觀。Eller稱,2011-2020年,中國和印度將產2000萬輛新車,這些新車對熱塑性硫化橡膠(TPV)和苯乙烯類嵌段共聚物(SBC)的需求將達1.1億磅。

Globally, thelargest automotive TPE growth potential is in China and India, where 20 millionnew vehicles could create 110 million pounds of new thermoplastic vulcanizate(TPV) and styrenic block copolymer (SBC) demand from 2011-20, according toEller, president of Robert Eller Associates LLC in Akron, Ohio.

在歐洲,汽車銷量的下降已經對TPE市場需求產生消極影響。至2020年,歐洲將產1470萬輛汽車,這輛的產量仍比2007年市場高峰期低8%。Eller說道,歐洲汽車市場恢復較為遲緩的原因有三個:第一消費者的購車欲望下降;第二人口老齡化;第三歐洲公共交通系統極為卓越。

In Europe,declining car sales have affected TPE demand negatively. By 2020, the regionwill be producing 14.7 million vehicles, a level that still would be 8 percentless than the market’s peak 2007 production. This slow comeback has been causedby a decline in consumer appetite for cars, an aging population and Europe’sexcellent non-auto transportation system, Eller said.

TPE在全球的增長市場根據類型而變化。SBC方面,增長市場包括包裝、汽車、電子工業、醫藥和電線電纜行業。共聚多酯的增長市場包括電子工業和生物塑料行業。汽車行業的發展將繼續帶動TPV的需求,而生物塑料和鞋類市場對熱塑性聚氨酯樹脂和泡沫塑料的需求將會提高。

Global growthmarkets for TPEs vary by type. For SBCs, growth markets include packaging,auto, electronics, medical and wire and cable. Copolyester growth should comefrom electronics and bioplastics. The auto sector should provide future growthfor TPVs, while thermoplastic polyurethane resins and foam should see improveddemand from bioplastics and footwear.(關注微信:polytpe,然后回復:“TPV”即可查看更多關于TPV資訊)

同時,Eller還指出了TPE材料的一些潛在新應用,包括汽車后三角窗的密封件,TPV和SBC可以取代PVC和EPDM。

Eller — whopresented his most recent TPE outlook at the TPE 2013 conference in Germany inOctober — also cited some potential new applications for TPE materials. Thoseapplications include encapsulation seals for auto rear quarter windows, whereTPVs and SBCs could replace PVC and EPDM.(關注微信:polytpe,然后回復:“EPDM”即可查看更多關于EPDM資訊)

因耐熱性強、易加工且可以粘附在尼龍上,TPV還可用于通風管管口。Eller還補充,在較短的通風管,TPV可以取代EPDM。

TPVs also could beused in air duct cuffs, where the materials offer heat resistance, ease ofprocessing and adhesion to nylon. TPVs additionally could challenge EPDM inshort air ducts, Eller said.

除了汽車領域,SBC可用于制造化妝品瓶和藥瓶軟蓋。就TPE內部而言,Eller稱TPV在汽車領域正成為一種商品,但SBC在這一領域已與TPV形成競爭之勢。

Outside ofautomotive, SBCs have potential in soft-touch overmolds for closure caps incosmetics and pharmaceuticals. Within the TPE sector, Eller explained that SBCsincreasingly are competing with TPVs in the auto sector, where TPVs arebecoming a commodity.(關注微信:polytpe,然后回復:“TPV”即可查看更多關于TPV資訊)

長期來看,Eller預計TPE供應商無論在數量或產品多樣性上都會增加。對TPE制造商來說將會更加難以控制自己的知識產權。全球TPE市場也會出現更多等級、更多競爭以及更大的兼并興趣。

Longer-term, Ellersaid that he expects TPE suppliers will increase in both in number and diversity.It also will be more difficult for TPE makers to control their intellectualproperty. The global TPE market also will see more grades, more competition andmore interest in acquisitions.

類似交易在2014年已有發生:SBC制造商美國科騰高性能聚合物在1月收購臺灣SBC廠商LCY化學公司,收購后該材料公司年銷售額達20億美元。

One such dealalready has taken place in 2014, when SBC maker Kraton Performance PolymersInc. of Houston in January merged with the SBC business of Taiwan-based LCYChemical Corp. to create a materials firm with annual sales of $2 billion.(關注微信:polytpe,然后回復:“科騰”、“李長榮”即可查看更多關于這兩個公司的信息資訊)

來源:plasticsnews,整理:粵高分子(微信號:allsebs)

source:www.plasticsnews.com

========

下集精彩預告:《熱塑性彈性體在汽車行業應用的優勢》By:朱熠 中國第一汽車股份有限公司技術中心請繼續關注我們公眾帳號:polytpe

每日精彩內容,訂閱吧!

高分子論壇,關注熱塑性彈性體,3D打印耗材,穿戴設備用的高分子材料,一所沒有圍墻的大學。老師,你我他;學生,他你我,能者為師。為著一個共同的目標和希望:分享知識,創造價值!歡迎關注我們公共訂閱號:艾邦高分子(ID:polytpe)。論壇平臺服務號:高分子網(ID:cnpolymer)。論壇地址:

http://bbs.polytpe.com

更多關于汽車,以及VOC的文章,請關注微信公眾帳號:polytpe,然后回復“VOC”,“汽車”

近期我們推出以下文章:

有機硅RTV在汽車領域的應用

專業解讀:特斯拉等汽車充電樁給高分子以及TPE產業帶來什么?

TPE汽車內飾件有機揮發物VOC檢測

[動態]杜邦亮相德國K展針對汽車行業推出新型彈性體

[汽車]TPE用于汽車可剝性的保護膜

[會議實錄]淺談汽車橡膠密封制品技術應用

[會議實錄]TPE在汽車行業的應用以及趨勢-粵高分子

[會議實錄]高性能彈性體在汽車配件中的應用

[會議實錄]新型熱塑性彈性體在汽車上的應用

TPC是什么?汽車用熱塑性彈性體介紹

詳解PC/ABS中VOC來源

【圖】專業介紹汽車VOC測試

汽車主機廠主流VOC檢測方法

全球汽車制造商測試塑料的VOC排放

《TPE資訊》第20140613期-TPE以及塑料在汽車領域應用的最新資訊!

直接閱讀原文即可查看更多關于“汽車”、“VOC”的文章

始發于微信公眾號:艾邦高分子